GRATINGS, TERMINOLOGY

We have compiled a list of the terms we use when we name gratings.

GRATINGS, TERMINOLOGY

We have compiled a list of the terms we use when we name gratings.

Gratings

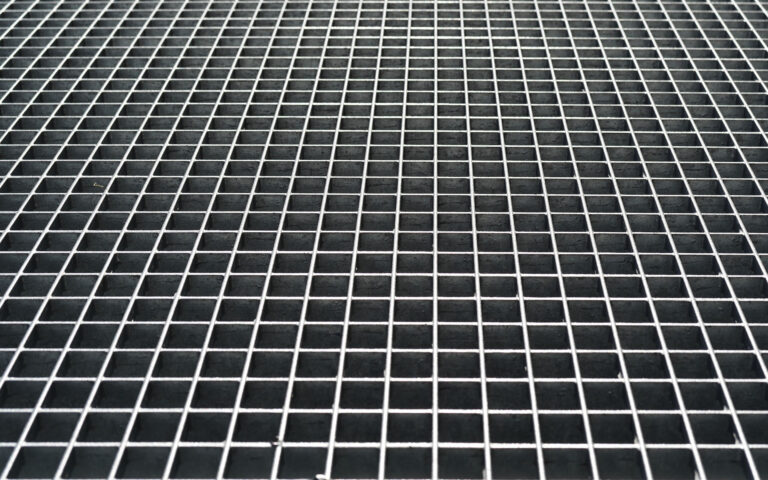

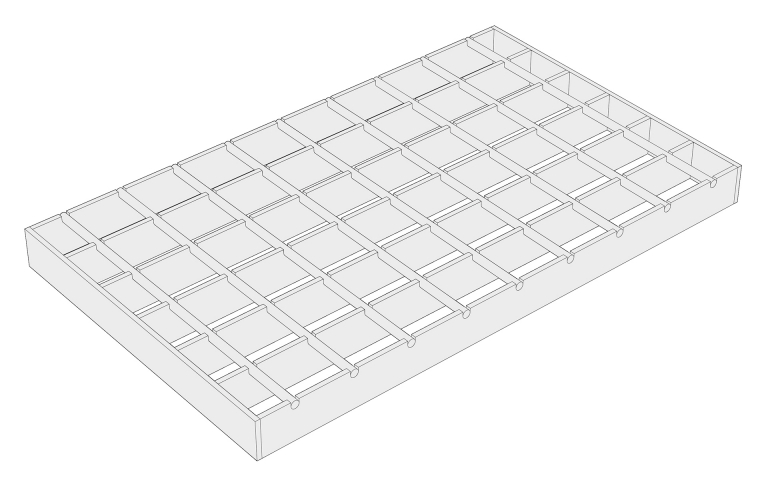

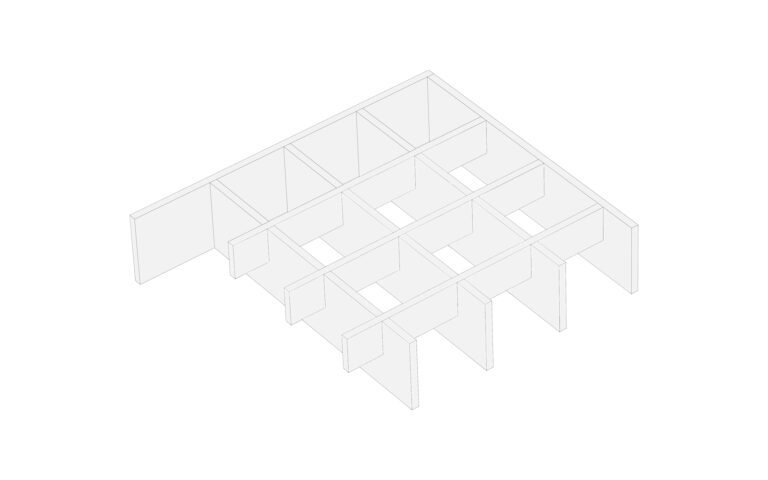

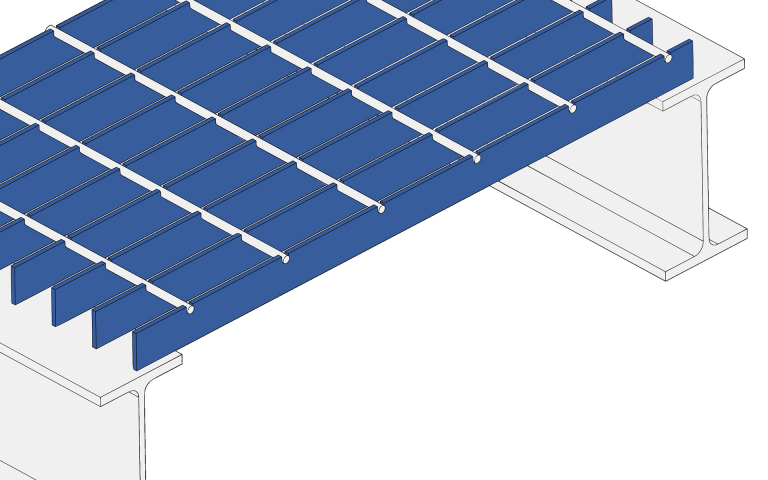

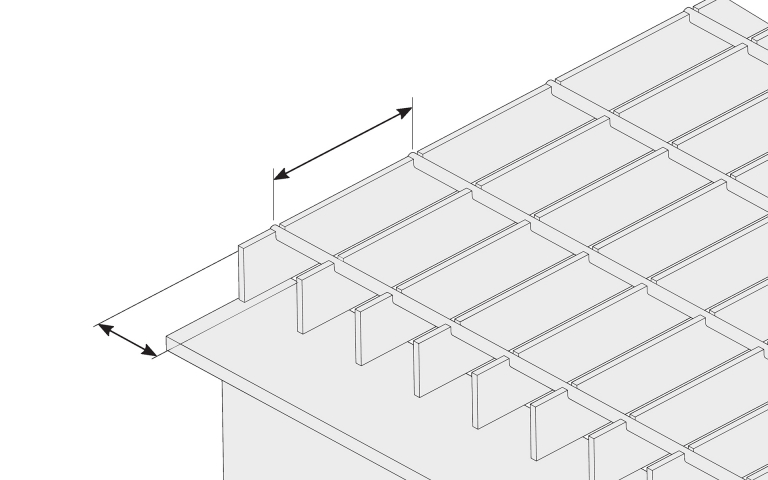

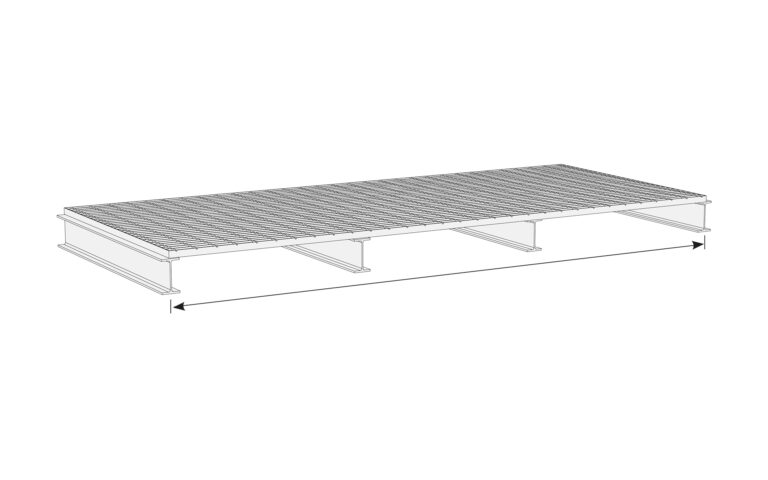

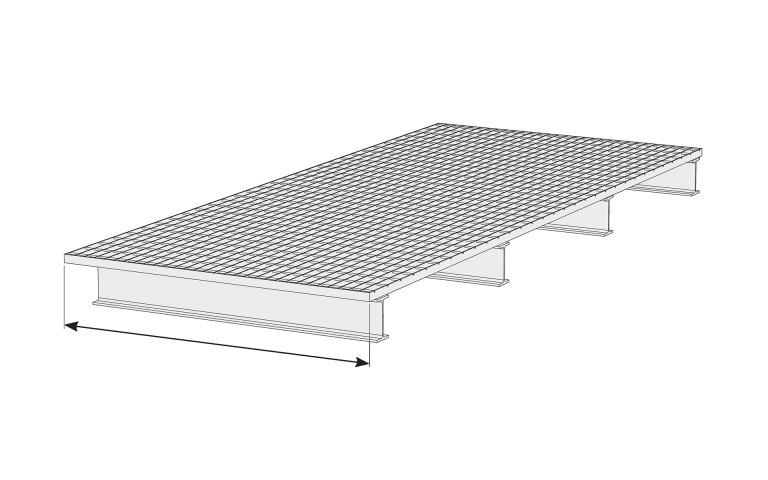

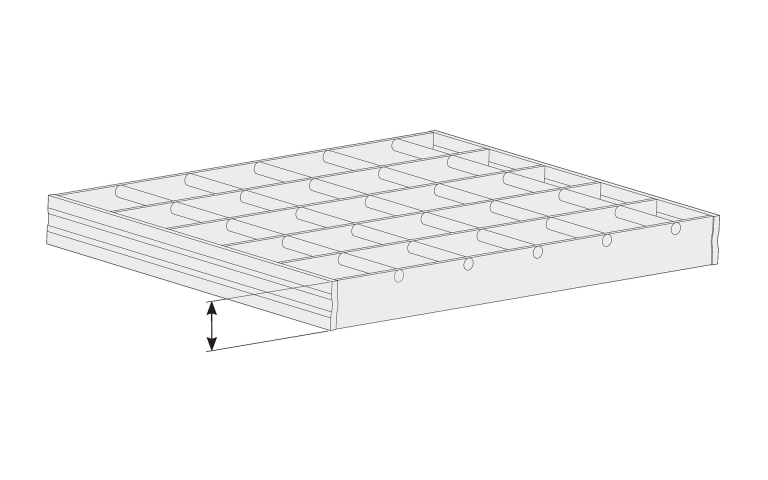

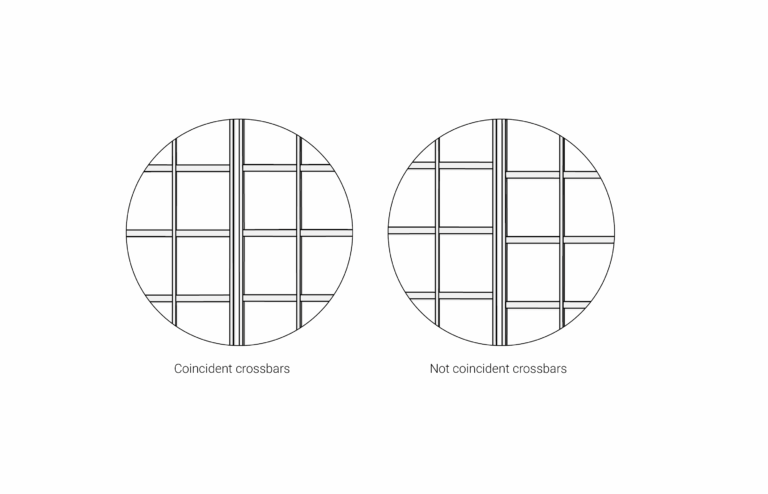

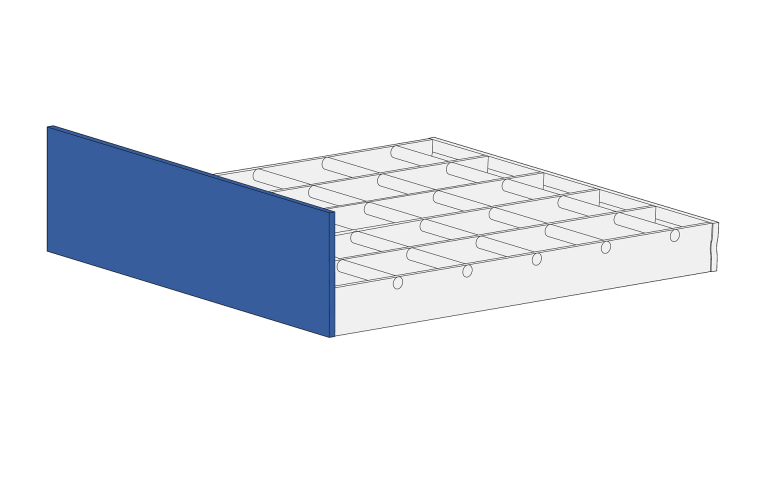

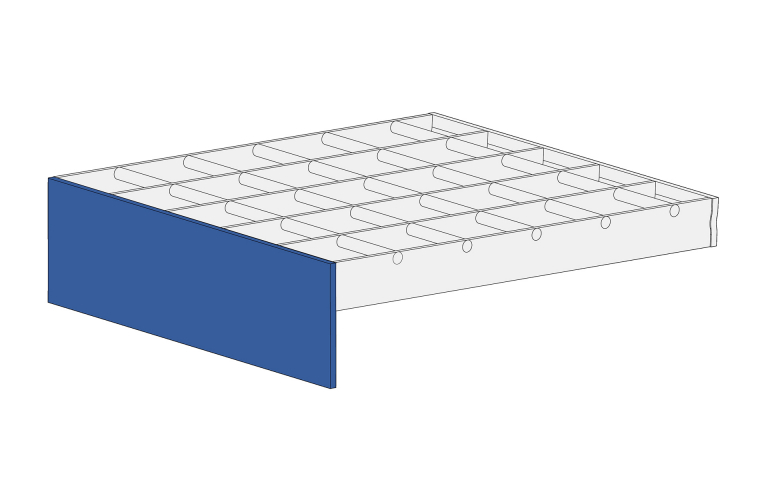

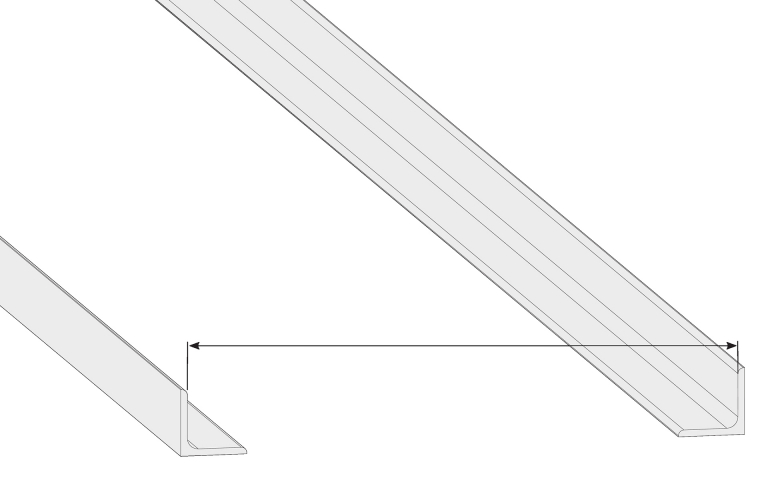

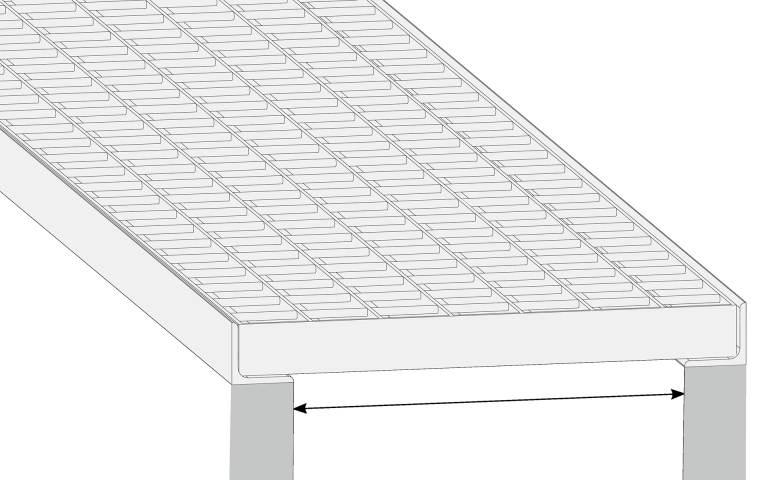

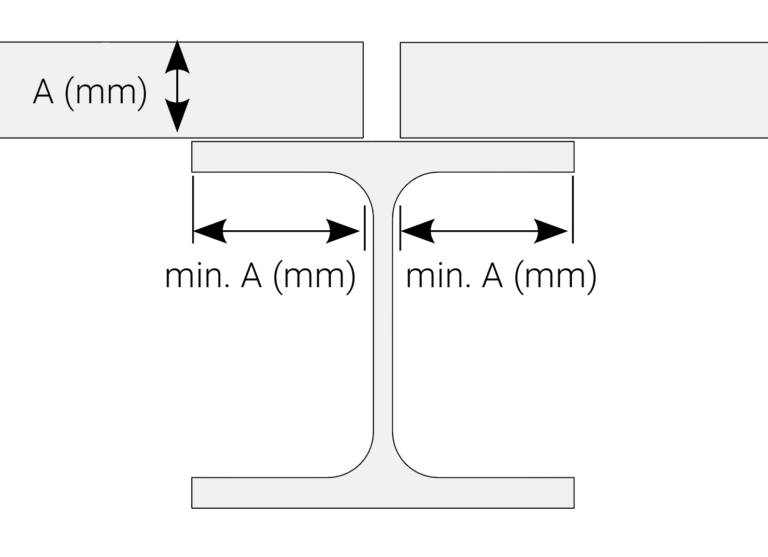

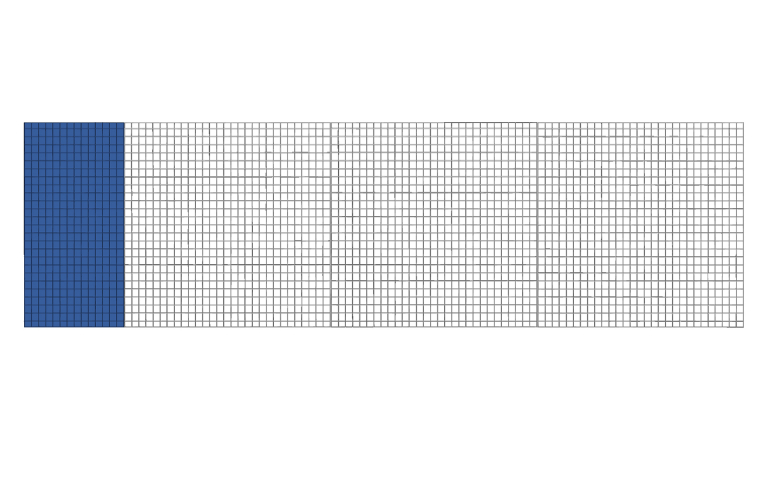

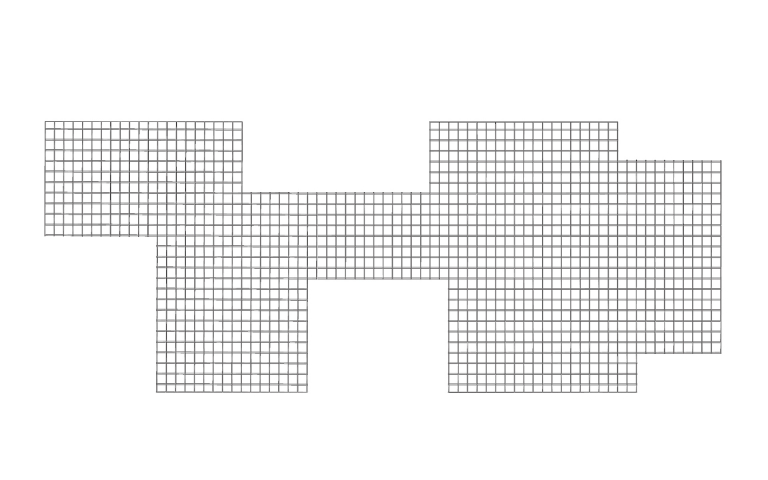

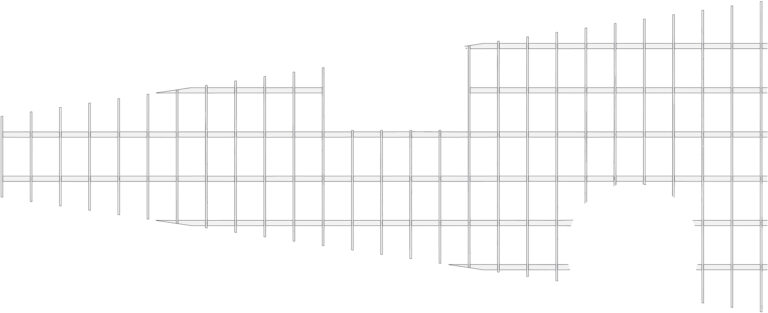

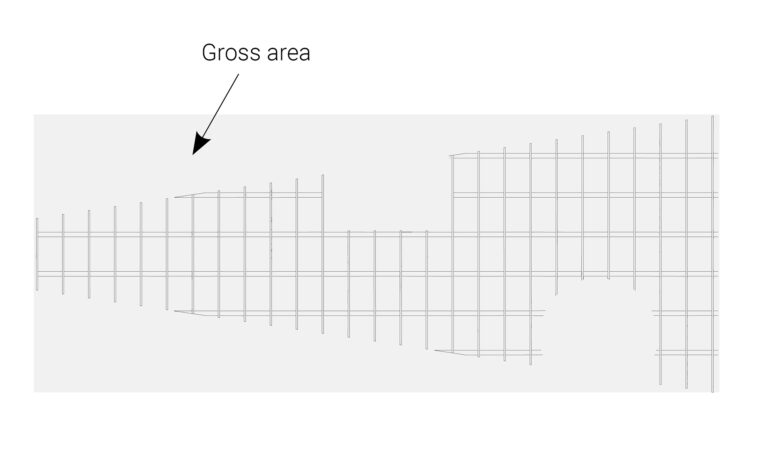

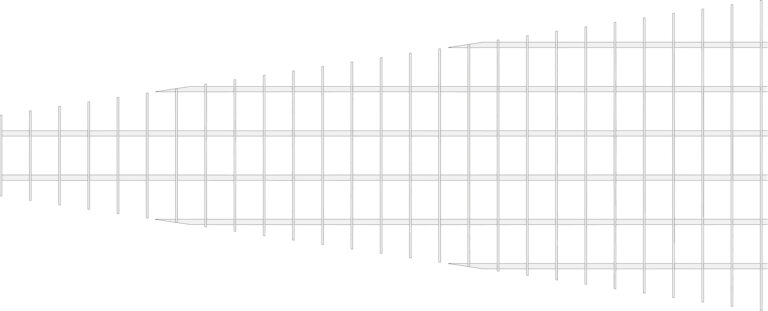

Gratings are manufactured in many different versions for the most varied of applications. We have compiled explanation for the various technical terms that are usually used when we name gratings and their component parts.

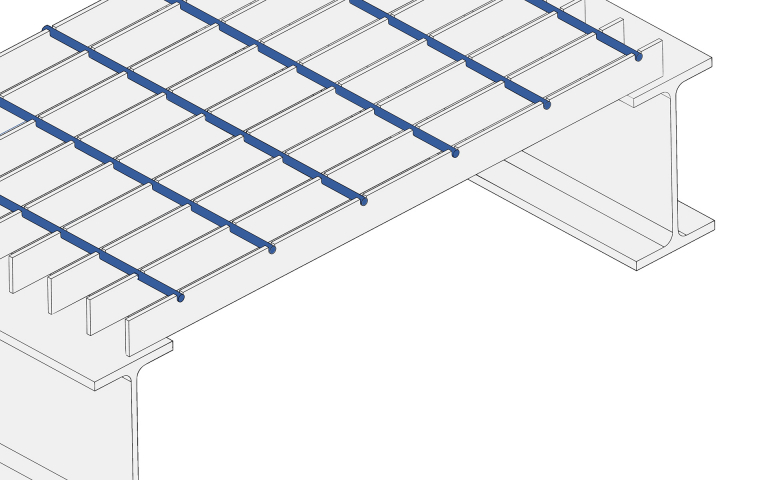

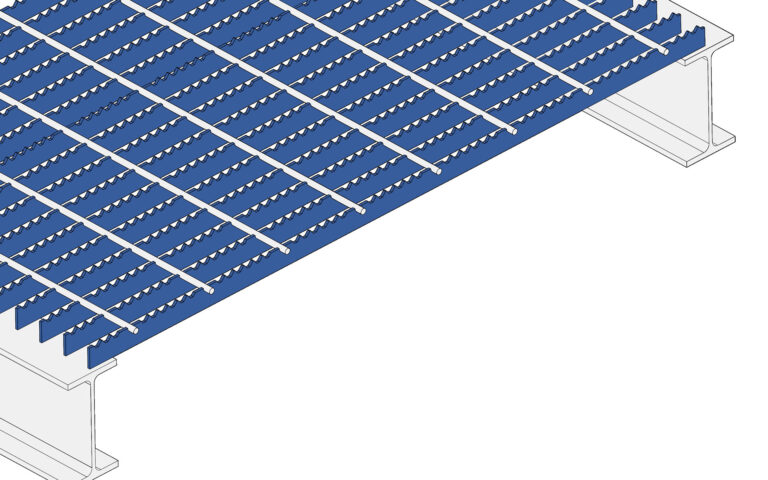

Weland pressure welded grating is manufactured according to the resistance welding method. The load bearing bars are joined with the cross bars under high pressure and high amperage. This manufacturing method for pressure welded grating gives a welded joint at each connection between load bearing and cross bars. This provides the grating with extremely good durability, strength, and a high bearing capacity. Edging bars are welded perpendicularly to the bearing bars on the grating. Grating is made either from hot dip galvanized steel or stainless steel.

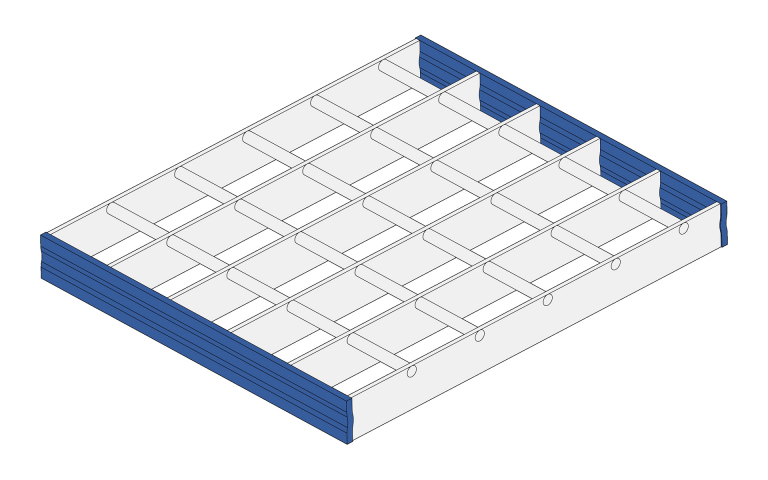

Type A type grating consists of flat steel bars that are cut into lengths for both the load bearing bars and the cross bars. The punched out load bearing bars are laid together with the cross bars to produce a mesh pattern, and the grating is supplied with edging bars on the load bearing bar ends. The grating is manufactured in steel, stainless steel or aluminium. We have a large range of entrance gratings, manufactured from Type A grating.