PUNCHING

Weland offers punching in both sheet metal and tubing in our modern production lines. We handle punching in both small and large volumes and are with you all the way from idea to finished product.

Unique possibilities for punching sheet metal

Punching is a highly efficient method of sheet metal processing that maintains high precision and flexibility. Weland has four machine lines for punching with unique properties to meet the changing needs of the market. The production lines are equipped with a punch, angle shears and automatic folding machines. All lines have a high level of automation and handle materials from coils or, alternatively, initial sheet metal to finished component. In the same line, we can punch, cut, shape, bend and stack parts, giving Weland considerable flexibility with short set-up times and high precision. Punching also provides great time savings compared to traditional folding in an edge press. This makes punching a multi-faceted and cost-efficient method for sheet metal processing. Weland is happy to help you with punching in both sheet metal and tubing.

Hole-punching and folding

Weland’s punching machine lines are equipped with several different tools whereupon we can handle most types of hole-punching, scoring, flanging and markings. One of the major advantages with our production lines are the panel folding machines, which automatically fold all sides in single or more complicated folds, e.g. double-fold or at the desired angle. Our panel folding machines are suitable for components intended for store fittings, shelving systems, tool walls and tray plates. Contact us and we will tell you more about punching!

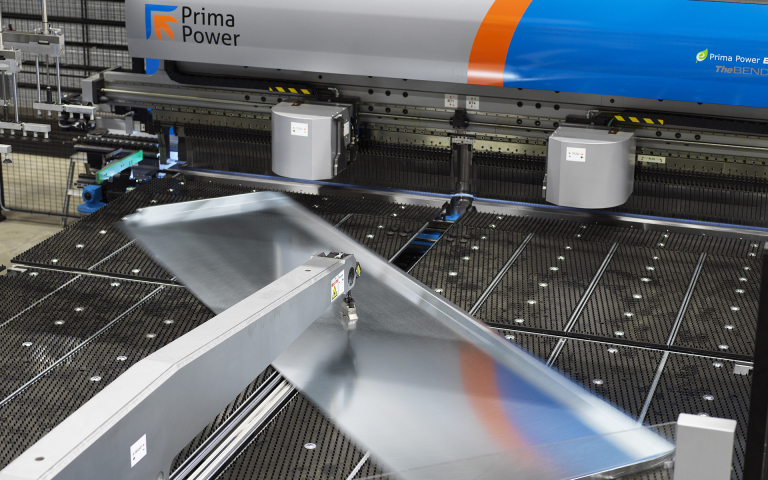

Sweden’s most modern machine line for sheet metal processing

Weland’s latest investment is a state-of-the-art production line which is completely unique. The machine line processes coils, which minimizes waste because the cutting length of the sheet metal can be optimized. The line is also suitable for punching from profiled metal sheets in sizes up to 4300 x 1500 mm. The line is suited to serial production and currently manufactures components such as store fittings, shelving systems, tool walls and tray plates. The larger and the more unwieldy the component, the more the reason to mass-produce. In this way, Weland can offer you very cost-effective punching. Need help with punching? Feel free to contact us!

Punching

- Material length: Up to: 4300 mm

- Material width: Up to 2500 mm

- Material thickness: 0.5 – 8.0 mm

- Hole punching: Max. 9 holes at a time

Bending

- Material length: Max. length (X): 3990 mm. Min. length (X): 285 mm

- Material width: Max. width (Y): 1524 mm. Min. width (Y): 190 mm

- Material thickness: 0.5 – 4.0 mm. Diagonal dimension (D) up to 4000 mm