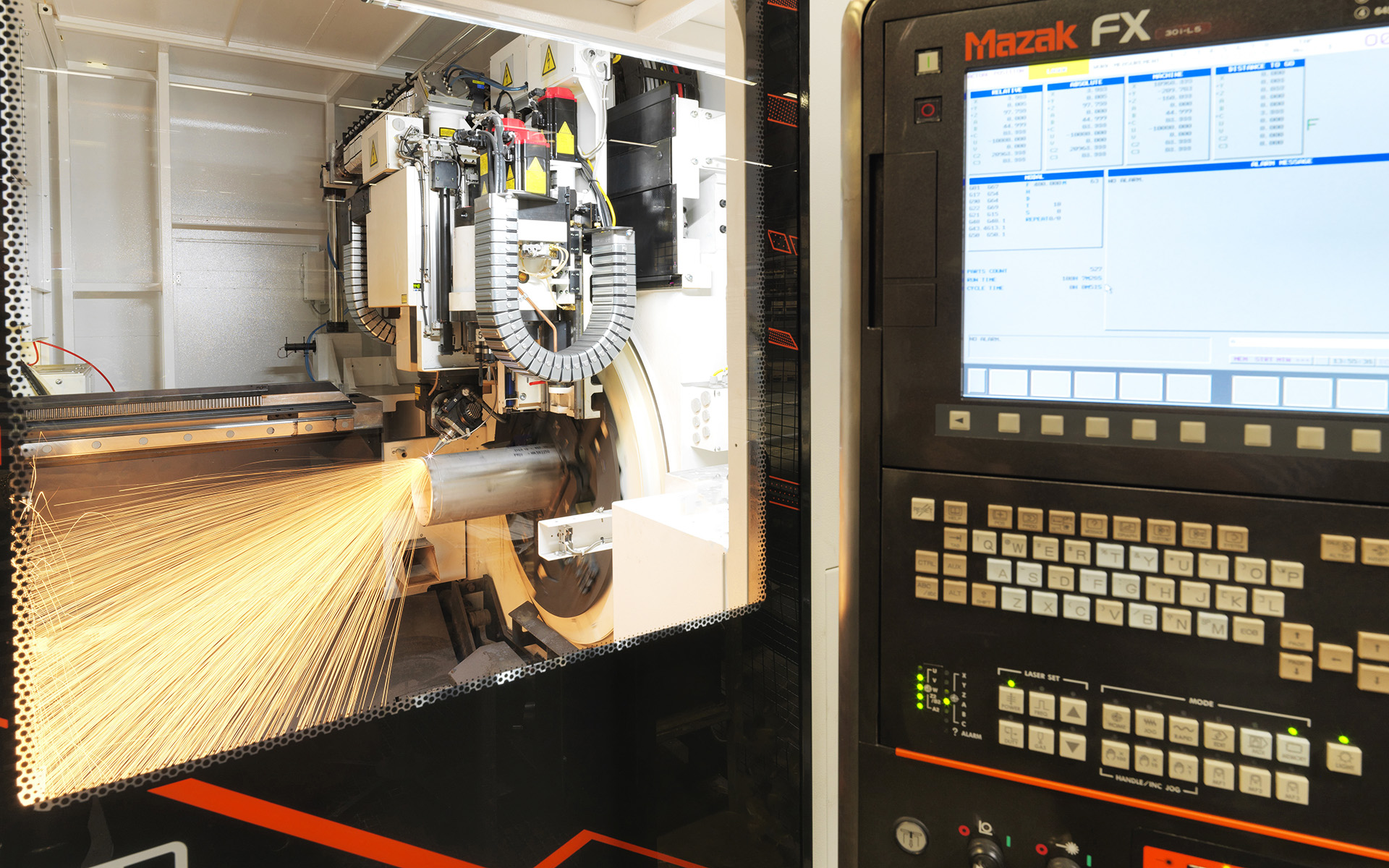

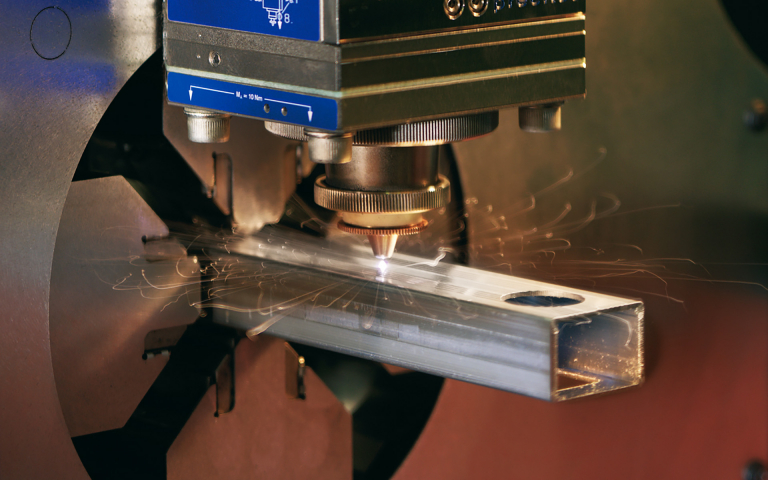

TUBE LASER CUTTING

We provide tube laser cutting in the majority of formats and dimensions. Our strength is based on a continuously updated fleet of machines, many years of expertise and great flexibility.

Large production capacity

We have many years’ experience and knowledge of tube laser cutting. We have some 20 machines for tube laser cutting with different characteristics such as, for example, threading and joint preparation. In our continuously expanding fleet of machines, we have the possibility to cut everything from small tube dimensions up to tubes that are 508 mm in diameter.

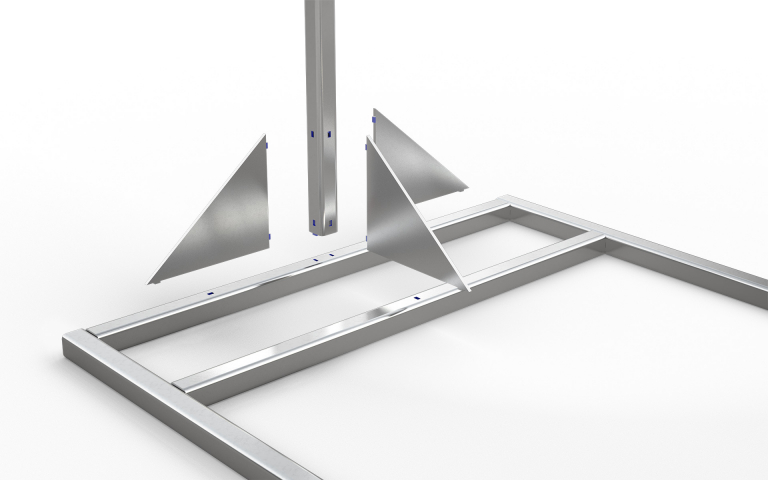

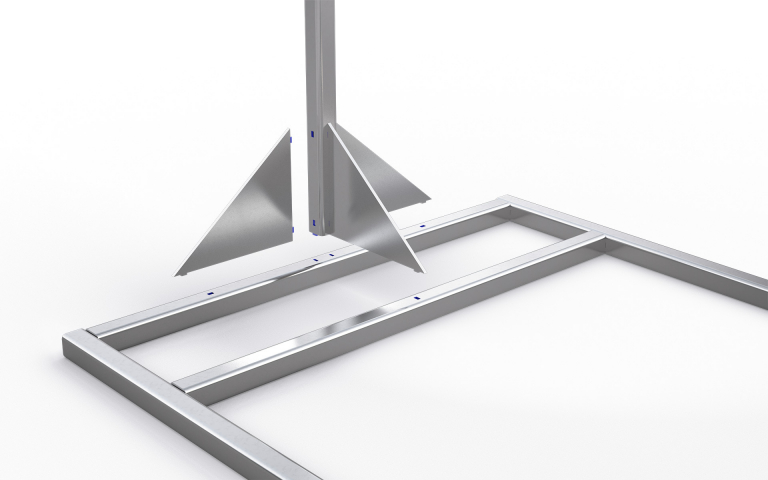

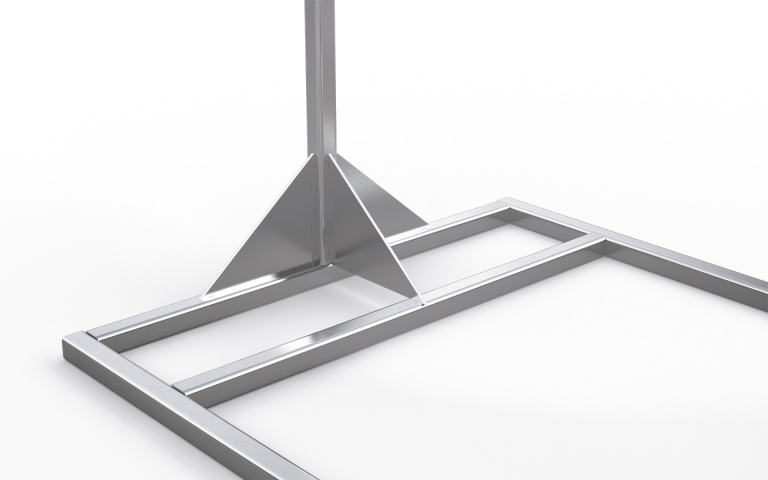

Tenon cutting

Once the details have been laser cut, the parts can be prepared with matching tenons and holes. These tenons and holes provide a perfect fit prior to welding. No measurement of the parts is required. Tenoning facilitates the assembly and joining of the parts and you obtain a perfectly assembled product. The welding rig is a high cost in the product development, with tenoning you avoid this cost.

Fixed cutting edge

Laser cutting of tubes with fixed cutting head is the traditional method for laser cutting tubes. The cutting head is fixed and always directed towards the centre of the tube.

Section surfaces in HF HRS sections are perpendicular to the plane surfaces. Cutting of indentations and cutting products with great precision and speed. This is a superior production method for both small and large batches.

Movable cutting head

Automatic cutting with movable cutting head (3D cutting) enables production of components where the use of laser cutting has not been possible before. For example, welding chamfers are cut without any need for finishing. Likewise, countersinks and threads can be cut at the same time as holes are made. “Edge-to-edge” tube joints with arched surfaces can be cut with great precision. The fit is superb when the surfaces are fitted against each other. Angled connections and tubes in different dimensions can also be cut. We have a large capacity with automatic feed of materials, even for thick dimensions.

Fibre-optic tube laser cutting

We can also offer fibre-optic laser cutting of tubes. Fibre lasers are a compact, effective and reliable method that has long been used within several other business areas. It is now also possible to use the technique for metalworking, which provides a number of advantages compared to traditional laser techniques. The energy consumption is up to 80 per cent lower, which provides a more environmentally friendly production. The fibre laser can also cut highly reflective materials such as stainless steel, brass and copper, which the market is now demanding.

Jumbo tube laser cutting

For heavy duty and larger profiles, we have equipped our fleet of machinery with two Adige Jumbo tube laser cutters. The machine has the capacity to cut tube up to ø 508 mm. This opens up entirely new production opportunities in the heavy duty segment, for example, the steel construction industry. In addition to round and square profiles, which can also be cut in oval, semi-oval and elliptical profiles, as well as rolled steel beams.

Unique opportunities for the construction sector!

- Max. material length for cutting: 18,000 mm

- Max. dimension: ø 508 mm or 400 x 400 mm

- Min. dimension: ø 10 mm or 10 x 10 mm

- Max. material thickness: 15 mm

- Max. weight: 3,600 kg eller 200 kg/m

- Tapping: M3 – M12