LASER CUTTING

Laser cutting is performed with great precision in our modern machine fleet. With expert and committed personnel, we are your given supplier.

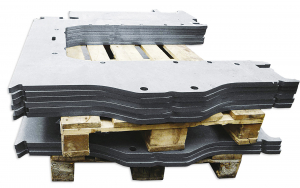

Large capacity

Weland has a large modern fleet of machinery for sheet metal working. We have the resources required to perform most metalworking processes with precision, skill and the highest quality. We have around 20 laser cutting machines in shift operation. In total, we have the capacity to cut more than 160 tonnes every working day. We are working constantly to improve the efficiency of our machine fleet and the majority of our machines are equipped with 10 kW fibre laser, which makes the production faster and more environmentally friendly.

Come to us, and make your ideas reality. We have good capacity and are at your disposal.

Prototype production

Laser cutting is a superb way of manufacturing prototypes. This is a very economical and quick method of production as you do not need to produce any special tools.

We are at the cutting edge, and we have invested extensive resources in digitalising our manufacturing, Industry 4.0. Our laser cutting machines are integrated in, and connected to, our ERP- and CAD/CAM system for monitoring productivity and availability. We can handle all commercially available file formats, and we are happy to help you produce digital drawings.

Cut surfaces and materials

The cut surfaces are completely perpendicular in laser cutting. Moreover, the cut surfaces are so uniform that there is, as a rule, no need for grinding.

Our machinery is constantly updated, and our most recent machines for laser cutting can handle sheet metal sizes of up to 6,000 x 2,500 mm. Large format sheet metal is available in stock.

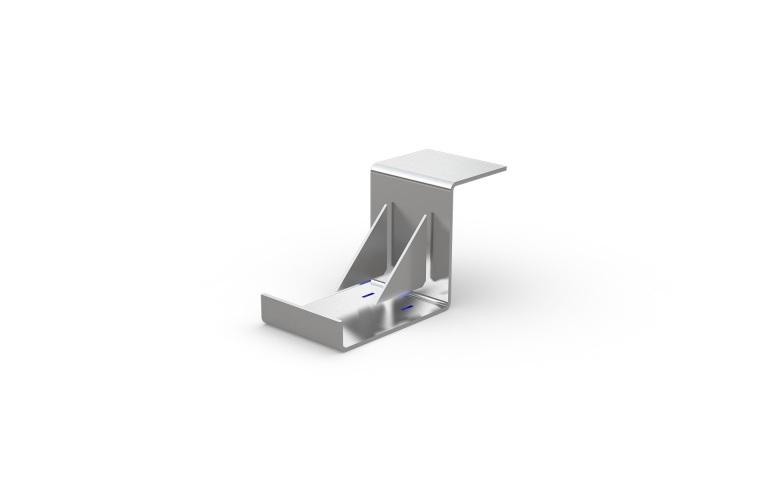

Tenon cutting

Already, while the parts are being laser cut, they can be prepared with tenons, mitres, notches and holes in the goods. This gives a perfect fit prior to welding without any need for expensive jigs. The tenoning facilitates the assembly and joining of the parts. You get a perfectly assembled product.